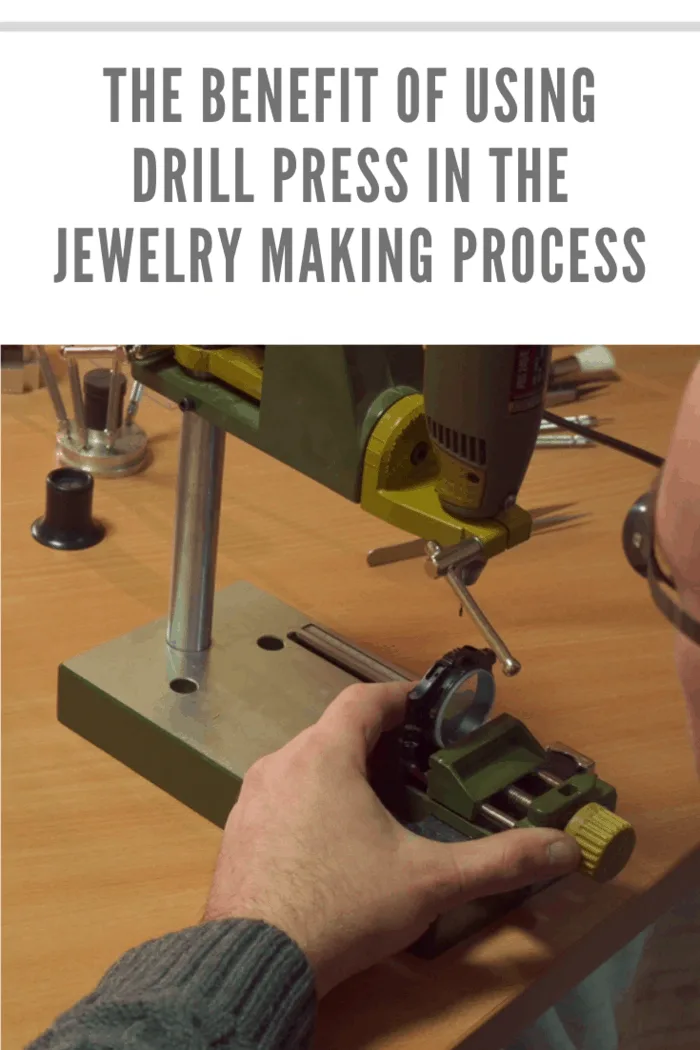

A drill press’s primary role is to drill and enlarge a cylindrical hole in different materials for making jewelry.

Jewelers prefer to look for the best drill press that can make the jewelry modeling process easy. The best drill press is one that makes molding and shaping jewel a convenient process. You can research the various models that exist and choose one that will work with the materials and techniques you are using. Get more info here, about drill press for jewelry making process.

When going through different brands, make sure each can take the central role of a performance-driven power tool. A drill press should be compact and portable to fit well on your workbench or stand. The drill press of choice should have the extra power to make holes in different materials for making jewelry. A drill press should offer balanced performance when using all its range of speeds and work with various drill bits.

By the time you decide to look for a drill press that is more powerful than a handheld power drill, you expect the following benefits.

Portability

Look at how portability will benefit you as a jeweler. It means a drill press that you can move from one corner to another without interfering with the production process. If your operation area is small, the use of a compact drill press with its critical storage unit gives you access to the chuck key. The compact nature of the drill press means you easily keep away when not in use.

When working off-site, you only need to carry the drill press to the second site and continue working. Using the drill press handling costs is not as expensive as those of the larger ones are.

Drill Press Offer Solid Design

A drill press has a unique tight swing designed explicitly for its use in jewelry design. The machine offers reliable depth stops if you look at the intricacies involved in creating small pieces.

The materials used in the design of the top and lower sections of the drill press offer stability when working in a space with many movements. The heavy base helps stabilize the drill in case of accidental tipping.

Versatility

A jeweler needs a tool that offers versatility in the form of speed. A standard one provides at least three operating speeds that offer accommodation to the type of jewelry material you introduce. The working surface should adapt to type because not all designs are similar. Some shapes do not the standard forms and may get at an undesirable angle that a good drill press can accommodate.

The worktable should have rack and pinion adjustments to allow for raising and lowering. The chuck can hold different drill bits that define the nature of the work of a typical jeweler.

Drill Press Safety Measures

- Run the drill at the correct rotation speed that of the diameter of the drill bit and material. This information is available in the user manual

- Always use a vise or a clamp attached to the drilling table

- Ensure that your drill is well-grounded when working on a material

- Use a proper cutting fluid that corresponds to the material you are working on

- Never remove chippings using your hand. Use a brush instead

- Reduce the pressure you are applying on the material the moment the drill bit breaks a hole

- Inspect the drill before using it to minimize the chances of using a blunt or dull brill

- Support your back when drilling on a material running parallel with you

- Taper shanks have large diameters and should be in a drill chuck. Only the straight shanks can be clamped in chucks

- Taper Shanker tools or drill sleeves should be removed using a hammer and a drill drift.

- Do not loosen the drill chuck when the drill is powered on

- If the drill bit coils inside the piecework, stop the machine and turn the spindle backward using your hands to release the bit.

Final word

As is already evident, using the drill press in the jewelry-making process gives the jeweler the convenience of using different materials and designing more jewelry pieces. The idea is to purchase the most reliable drill press, and you will start counting your benefits.