Hydraulic systems make some of the most modern construction achievements possible.

Used in the operations of things like cranes, forklifts, and other heavy machinery, hydraulic systems are an unseen factor in the workforce.

It’s easy to forget that these systems can actually break down if they aren’t cared for or maintained properly.

Because hydraulic systems are used in a variety of heavy work, it’s extremely important to follow standard cleaning and inspection procedures.

Here are the steps required to perform a hydraulic system flushing procedure properly.

How to Properly Flush Your Hydraulic System

1. Remove the Fluid

You’ll first want to get rid of all the old fluid in the machine.

This will also help you determine if there’s water mixed in (Power and Motion).

Ideally, this will be done when the fluid is at operating temperature.

Often this will require that you attach a pump to remove all the fluid from the reservoirs, cylinders, lines, and filter housings.

It’s important to make sure as much of the old fluid is out as possible.

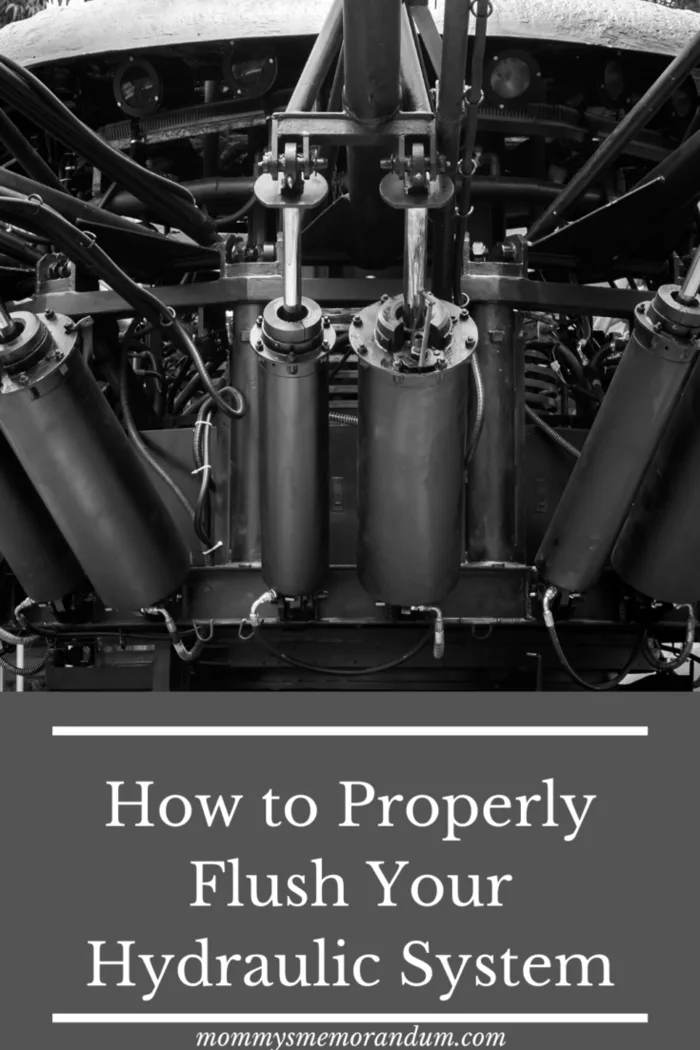

2. Wipe Out Excess Fluid

To get the rest of the fluid out, you’ll want to use a clean rag to wipe out all the cavities of your system.

Use some elbow grease to remove all the sludge and gunk from your system.

Look closely for any pitting that may have resulted from the interior cleaning of the system.

3. Add Flushing Fluid

The next step is to add flushing fluid up to about 75% of the full capacity.

You want to choose a flushing fluid with the same general thickness as the operating fluid, says Machinery Lubrication.

While doing this, you want to stroke the valves often to ensure the flushing fluid is pumping completely through the system.

This will help remove the junk you couldn’t get to with the rag.

After this step, you’ll want to clean the reservoirs once more after you drain the filters.

4. Add Operating Fluid

Once you have drained the filters and wiped out the reservoirs, you’ll want to add your standard operating fluid to capacity and prime the pump.

After this, allow the machine to run sporadically for a maximum of five minutes.

Allow the machine to rest after this to ensure it was flushed accurately.

After this, you can run the pump longer to ensure the new fluid cycles through the system.

Keeping a hydraulic system working well isn’t hard as long as you perform regular maintenance and cleaning.

Be sure to follow your owner’s manual for the recommended cleaning time frames for when to flush your hydraulic system and other maintenance.